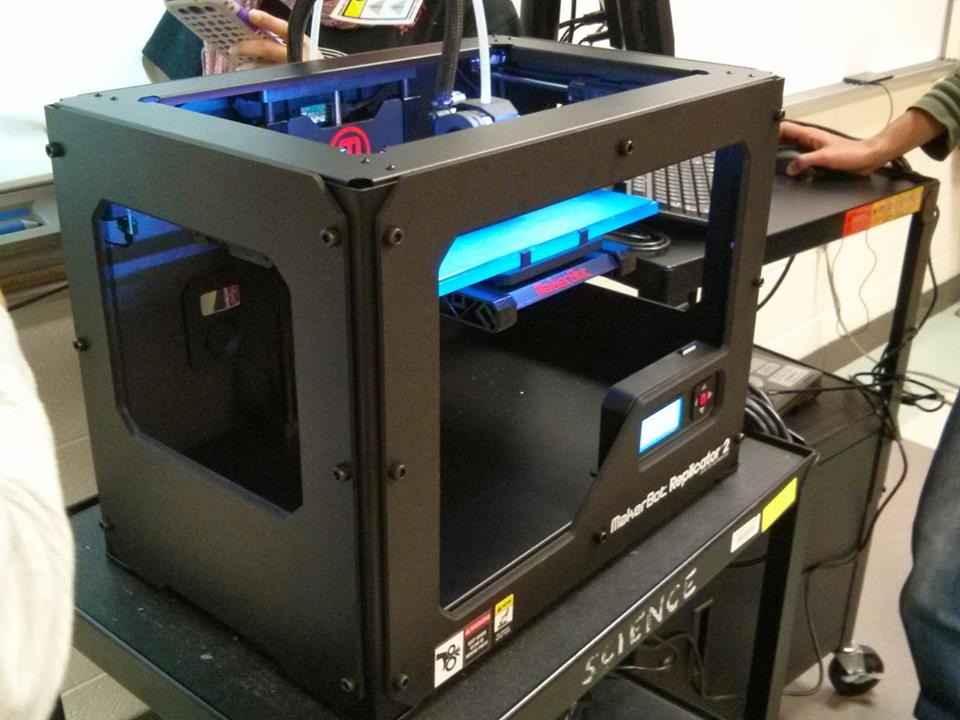

Photo courtesy of the Steel Hawks.

On November 26, the Steel Hawks huddled excitedly around the newest member of their team—a three dimensional printer. About fifteen minutes later, they watched in awe as a series of plastic chain links replicated before their eyes, with much bigger plans in mind.

“Watching a printer should seem boring, but we were all engrossed even though it took a while,” recalls junior and Robotics team member Abrianna Reddy. “I think that the reason it seemed so amazing to me was because we’re used to putting parts together to create our robot, and printing parts themselves is a completely different kind of creation. We build our robot from scratch, but this is “from scratch” on another level.”

Located in room 619, this innovative mechanism uses filaments to create layers that form a solid three-dimensional object out of a digital model. The Steel Hawks’ mentor, Priscilla Wong, suggested that the team purchase the device after reading an article about how Makerbot Industries was sponsoring 3D printers for teachers.

“Since the Robotics team had discussed purchasing one earlier this year but had then opted not to because of the shortage of funds, I thought it was still a good opportunity for us,” she said.

According to members of the Robotics team, the device is fairly simple to use.

“It’s much like a 2-dimensional printer, but with an additional axis; and rather than printing ink, you’re printing, in our case, plastic,” explained Robotics programming secretary, junior Neil Chen.

Although the objects produced by the printer have so far been trivial, there are several long-term ways the printer will benefit the team.

“Build season will definitely require the most use of the printer but we are already using it to print some past prototypes to learn more about 3D printing,” said Robotics co-captain, senior Rafal Chudzik.

When there are uncommon or costly parts needed to further build or complete a robot, the part can be designed virtually using computer-aided design to create a digital blueprint. That blueprint can then be put through the 3D printer, which layers the filaments and creates the piece. This saves the Robotics team time and money that would have been spent on obtaining the exact part.

“3D printing the component ourselves can cut down cost and time, as well as provide a unique learning opportunity, as team members will be able to work with a rapidly developing technology,” said Neil.

According to Robotics Head Coach Joel Heitman, the printer will also allow the team to “see the feasibility of a design” by producing a reduced model of it.

Robotics aside, Mr. Heitman noted that the printer will enable students to think “outside the box” by providing opportunities to use it to their advantage in other fields of interest, such as fashion.

Communications secretary junior Ian Sun agrees, saying that the 3D printer will increase the “importance of engineering in a humanities school” and said that the team may even start an in-school print service to show-off its capabilities.

Ian also points out the benefits of a 3D printer outside of THHS, such as its ability to produce prosthetic body parts. He described it as an “invaluable tool that has nearly limitless possibilities.”

The team looks forward to using the printer throughout the season.

“I never dreamed that I could actually use a 3D printer,” said freshman Naomi Chiu. “It seems really cool, and I can’t wait to work with it.”